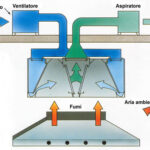

Choose our systems to clean and remove grease from kitchen and food preparation area sunction systems.

Reduce the risk of fire for your customers

Remove bad odors resulting from organic residues deposited in the ducts

To operate correctly, it is necessary to do an inspection of the premises and establish cleaning regulations.

To carry out the cleaning correctly, it may be necessary to install access doors through which you can physically work inside the duct.

To clean it is necessary to insert an alkaline and foaming chemical product inside, the foaming base helps the solution to adhere better to the walls and increase the contact time on the dirt.

But what is needed to carry out the work?

1) Single-phase electric skimmer, 25 or 50 litres, complete with compressor

2) Electric or pneumatic brushing machine: which is better? The choice is subjective, but the electric brush allows for greater freedom of action and is not dependent on the compressor, which limits movement and is, in effect, an additional machine on the working site, and one that is also noisy.

3) Degreasing chemicals, absorbent sheets to contain liquid dirt, plastic sheets to cover equipment, manual scrapers, with this dirt is also necessary to act manually.

4) Liquid vacuum cleaner and a sprayer to rinse away dirt, and it’s best to also equip yourself with a small pressure washer to clean the exhaustion air outlet and any components that can be dismantled for cleaning.

OUR TRAINING CENTER CAN ASSIST YOU IN CARRYING OUT THESE WORKS SAFELY AND IN COMPLIANCE WITH INTERNATIONAL PROTOCOLS